Maiden flight

Successful maiden flight

Any pilot can describe the mechanics of flying. What it can do for the spirit of man is beyond description.

Barry Goldwater

Successful maiden flight

Running our initial CFD analysis.

Data corresponds to our previous calculations.

Wing elements have been cut - they need to be assembled and laminated. The structure of the fuselage needs to be cut and built. Nose structure needs to be laminated.

Tim Vettšinov wrote a thesis paper on OpenUAV tail volume calculations. Now we need to build the tail of calculated size.

Steerable nose-wheel needs to be designed and built.

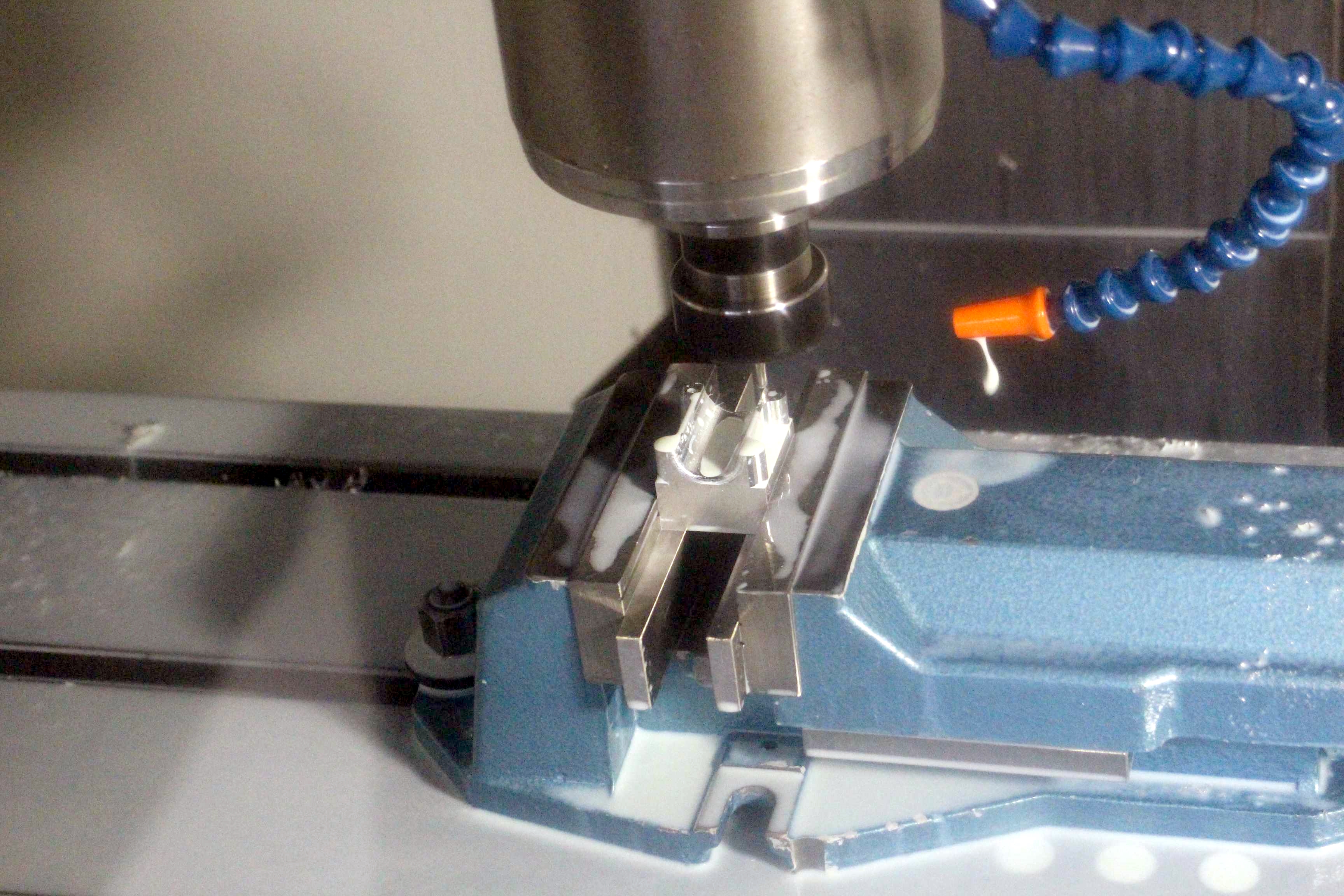

We use CNC machines to cut the aluminum clamps to connect the tubes.

The project could use some input for better mechanical-engineering.

The team high fives for the finished motor-mount assembly.

It is CNCd from laminated carbon sheets.

Positive mold for fuselage parts lamination

Fuselage will have a laminate shell panels,longeron tubes and bulkheads form the support structure inside.

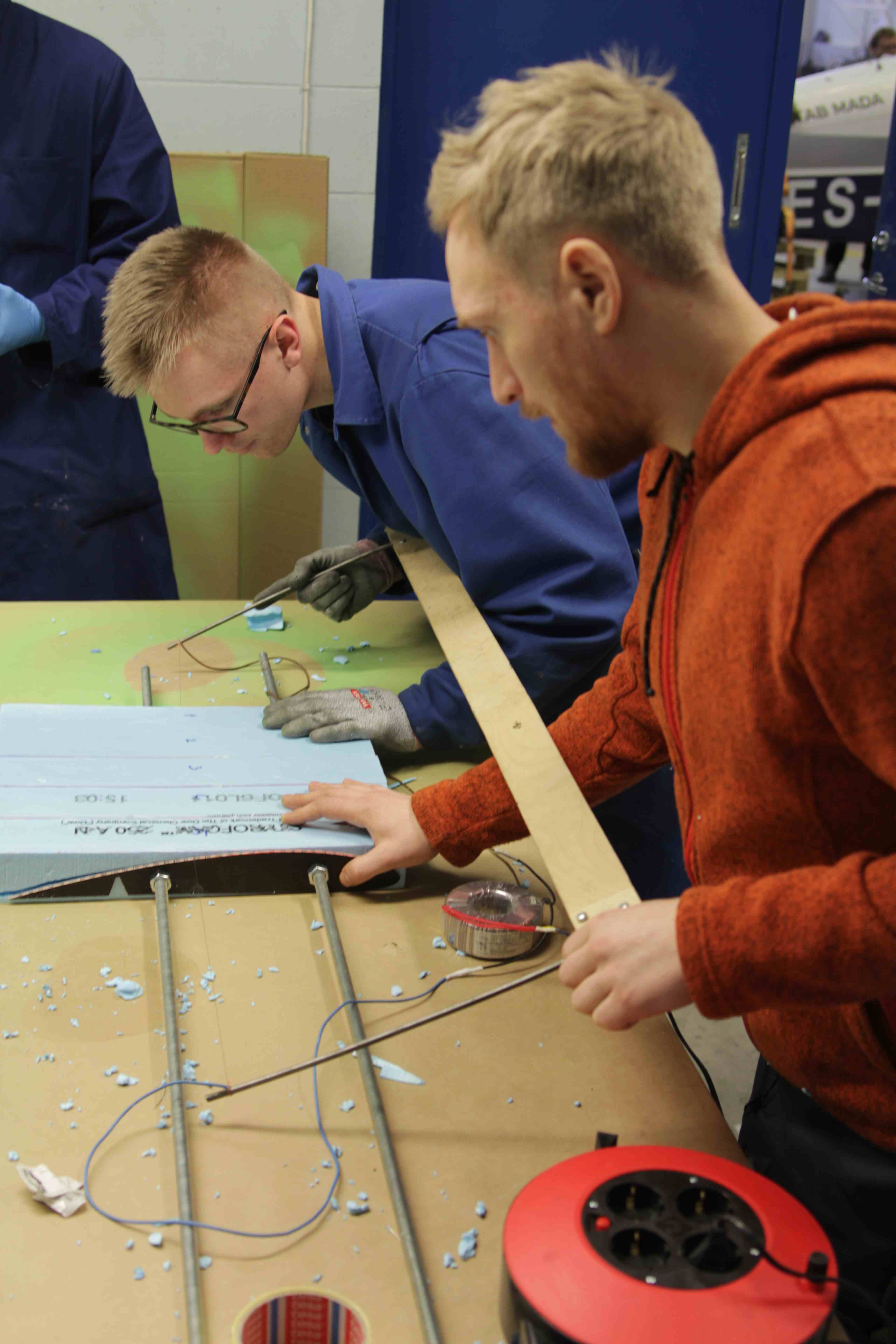

Cutting foam cores for the wings

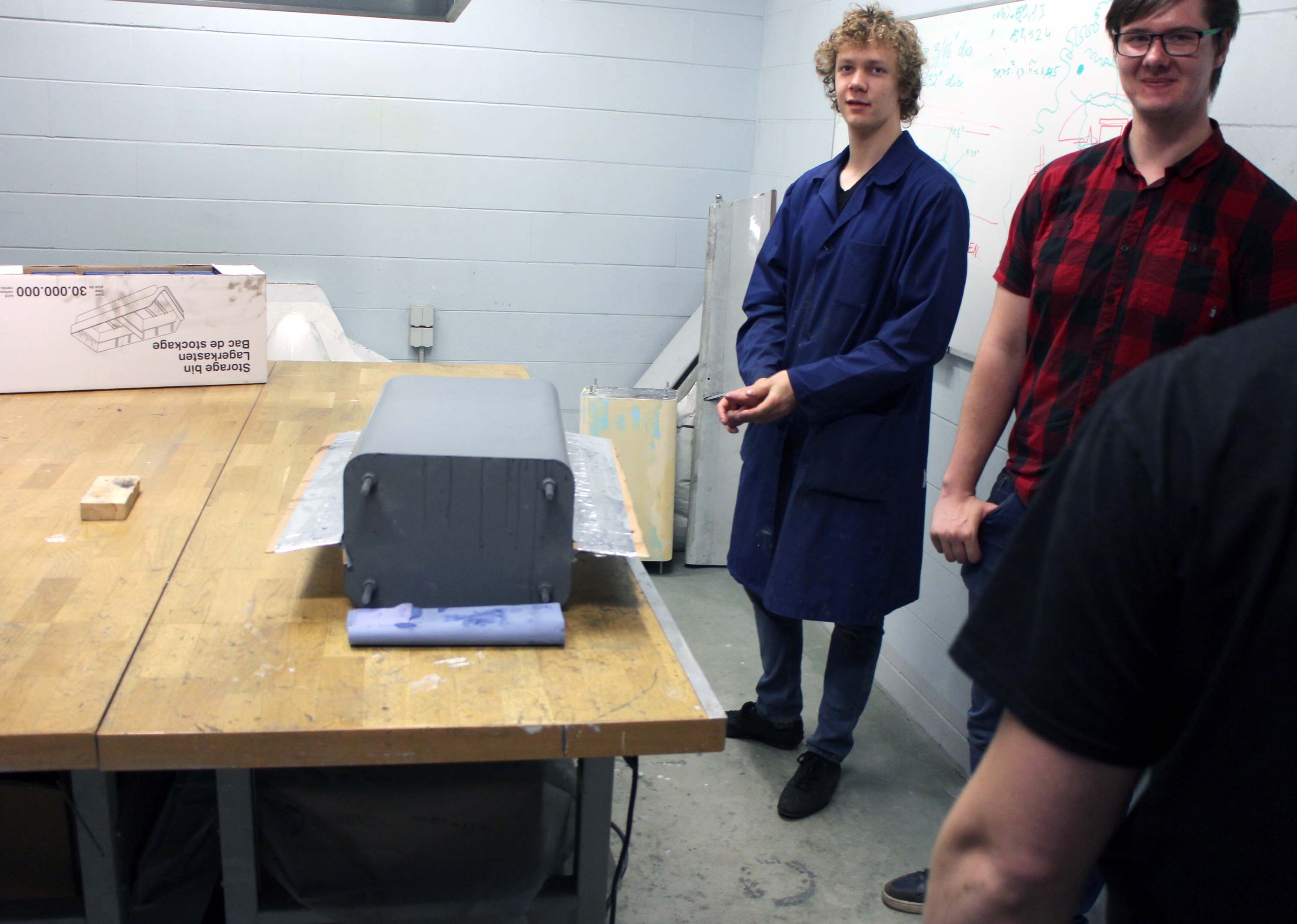

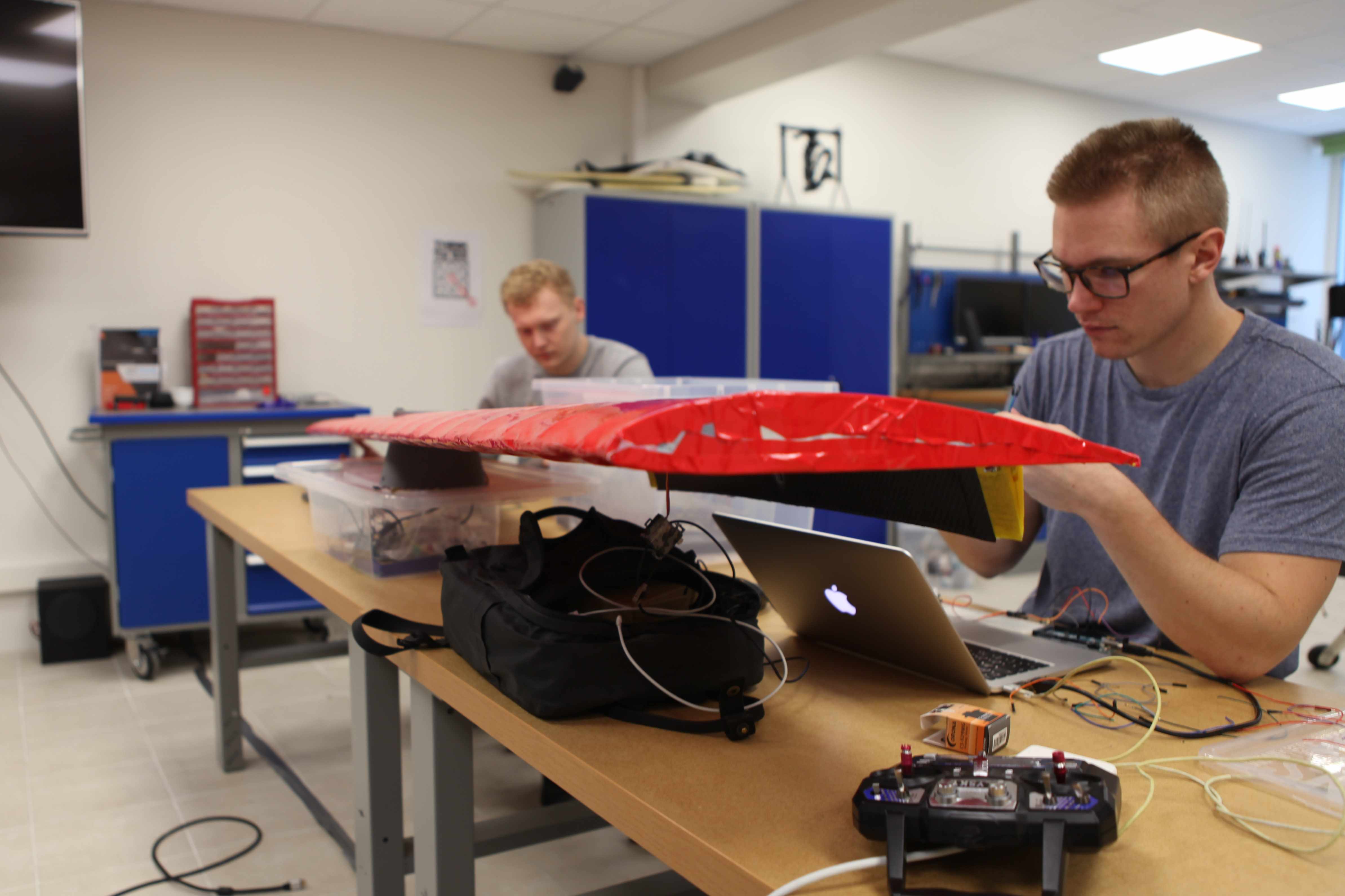

Students studying the previous prototype wing.

Our new wing is going to be foam-filled and use an innovative hinge construction.